with Base Double Octagonal Acrylic 30g50g Cream Bottle Diamond-Shaped Senior Cosmetic Packaging Materials

Basic Info

| Customized | Customized |

| Eco-Friendly | Eco-Friendly |

| Certification | ISO |

| Usage | Cosmtic |

| Material | Plastic |

| Type | Small Package Tank |

| Industrial Use | Personal Care |

| Use | Skin Care |

| MOQ | 5000PCS |

| Keyword | Acrylic Cream Jar |

| Printing | Silk Screen Printing |

| Service | 24 Hours Online Services |

| Lead Time | 25-35days |

| Transport Package | by Sea/Air |

| Specification | 30g 50g |

| Trademark | Winpack |

| Origin | China |

| HS Code | 3923000000 |

| Production Capacity | 500000 |

Product Description

New design Luxury 30g 50g acrylic cream jar with UV coating

MOQ:5K PCS

Lead time:25-35days

Customization: Support

Company Profile

3.Price of mass production private mold from 3,000 USDIn Europe and USA production of a private mold costs a fortune, sometimes reaching the level of 25,000 USD per mold set. However, due to lower labor costs and flexible production, here in China we set the record minimum price starting at 3,000 USD per mold set. Our molds can produce millions of bottles and whenever they wear out we replace the mold with new one free of charge. The cost of mold is refundable after 500,000 bottles ordered.

4.Minimum order quantity for custom design bottles only 10000 bottlesOur MOQ requirements for exclusive bottles, only 10000 bottles per run. That gives a great opportunity for the start ups and new projects to make a test run in the cosmetic market.5.Only 30-35 working days from concept design to bottle mass productionDue to our flexibility and speed of operations we manage to do the efficient work in much shorter period of time, which saves our clients a great deal of time and money.6.Significant cost advantagesThough the manufacturing of glass itself is highly automated, critical functions such as quality control need large teams of skilled professionals. Not surprisingly, the total cost of production in China, where manpower is among the cheapest in the world, is less than half of that in France and almost half of that in the US. With manufacturing facilities in North China, DEMEI Win-Pack is able to produce glass at significantly lower costs than its competitors in other parts of the world and deliver a sustainable cost advantage to customers.

FAQWhy choose us?

a. high-end products with professional packaging

b. positive delivery time with great transportation solutions

c. guaranteed quality with excellent support

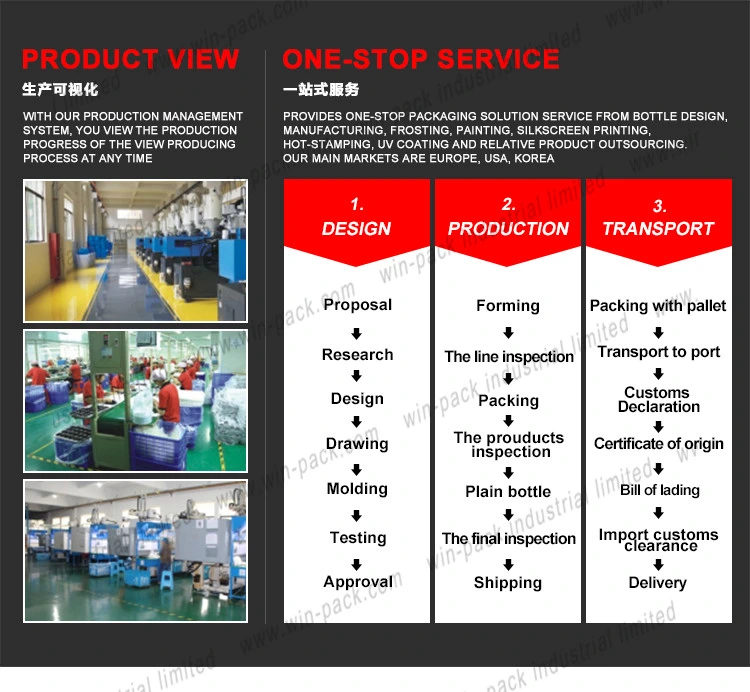

d. one-stop service: From Design to production, inspection, and shipment, we offer 100% guaranteed services

to all of our customer cover 35 countries.

Our Mission:

| W | workable marketing |

| I | incredible service |

| N | new resource integration |